Get started with High Performance HMI

Research shows that 90% of companies collect industrial data, but only 30% analyse this data. Even fewer, only 2%, use the information. With so much money being spent on data collection, why are companies not using the data better?

The answer may be simpler than expected. Although companies collect large amounts of data, it is often inaccessible and difficult to interpret. Fortunately, this is a barrier that can be quickly removed. In the four steps below, we show how High Performance HMI can make important, computerised information easily accessible.

Also read: Busting myths about High Performance HMI

Step 1:

Gather your team

High Performance HMI projects with high adoption rates share a common trait: They involve key stakeholders early on in the project. This helps solidify the common challenges, explore the best opportunities, prepare requirements, and test user interfaces. Ensure operators are included in this team, they will make or break the success of your program.

Step 2:

Build a workshop mentality into your review processes

It’s not enough to bring a group of stakeholders together, brainstorm and then send them on their way. Your stakeholders should have planned review checkpoints to optimise results. These checkpoints are critical for stakeholders to feel part of the journey, raise concerns earlier in the program cycles and ensure there is a highly likelihood of agreement.

Step 3:

Document and share more

Write everything down! This is a simple advice, yet it is a step that many overlook. Documenting decisions, learning and work plans is critical requirements to aligning the team and holding each other accountable.

Step 4:

Go after low-hanging fruit

At the start of a project there’s often a boost of excitement. But as the core team gets pulled back to their daily tasks, it can be difficult to maintain. An effective path to keep everyone focused on the long game, is to include low-hanging fruit milestones into your project plan. These keeps the team motivated to continue, while showing your future vision.

When it comes to designing High Performance HMI screens, there are a number of low-hanging improvements. Below are seven options that are easy to implement but makes a huge difference.

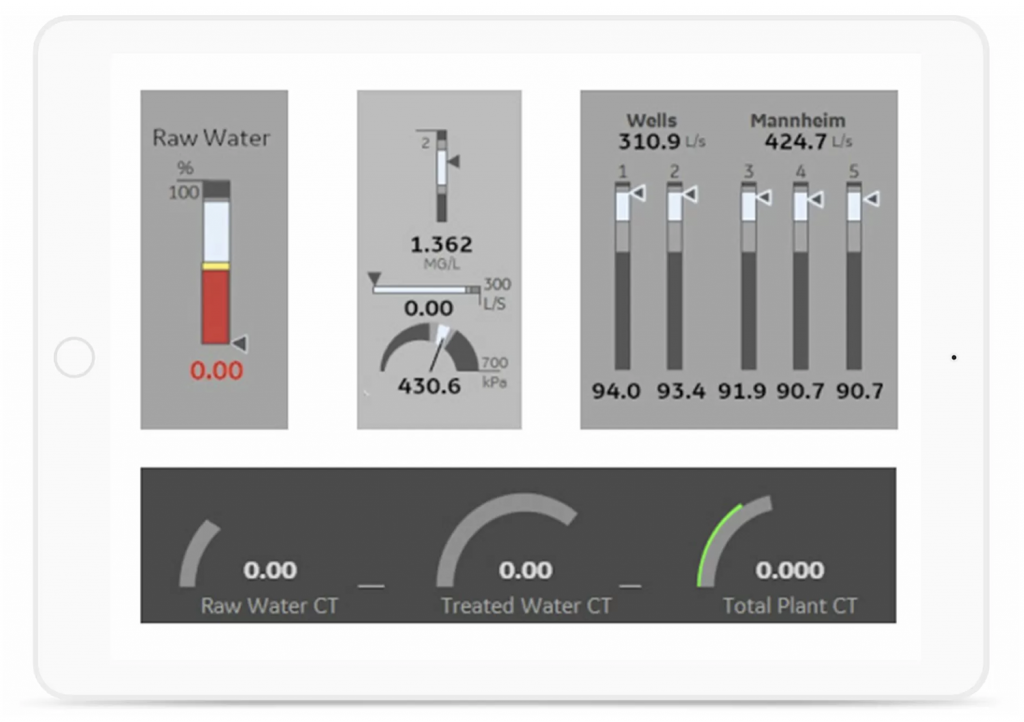

Clear, well-designed High Performance HMI screens can help operators immediately see process issues.

7 easy ways to get started with High Performance HMI

- Replace data links with meters

A picture is worth a thousand words. Instead of asking operators to link to data elsewhere, you can make it easy for them by visualising what needs attention.

- Display trending objects

Numbers don’t always tell the full story. By tracking trends, you can quickly see what might be improving or degrading over time. This will impact the actions taken by operators both immediately and long-term.

- Update piping/other PID elements

Illustrations that mimic piping and other system elements realistically can make it difficult for operators to quickly isolate issues. Simplify representations and make sure they are accurately depicting the current state of your equipment.

- Remove distracting visual elements

This includes gradient colouring, animations and flashing objects. These design elements distract the operator, causing the eyes to be drawn to them, instead of what needs attention.

- Add or modify background colour to improve contrast

Our eyes are trained to look for contrast. Changing the background colour of a display can improve the human eye’s ability to process visual information.

- Encapsulate process areas in a card

Make it easy for your team to see related processes next to each other, even if the physical footprint of your solution is separated.

- Consistent fonts, units and naming conventions

Consistency is key to processing visual information. This is a simple fix that can quickly make it easier for operators to focus on what’s critical.

This article is originally written by Aaron Knight. Read it on GE Digital’s website here.