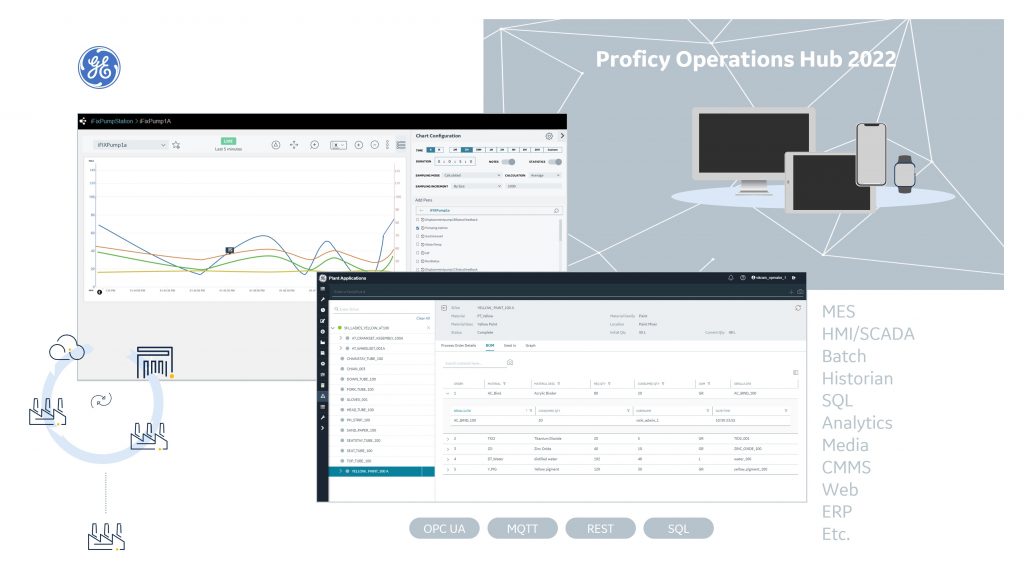

Proficy Operations Hub Enables Collaboration and Continuous Improvement with Centralised and Remote Visualisation

- Updated software delivers actionable information with a cross-business digital operations hub

- New portfolio-wide data flow editor saves time and increases visibility by automatically integrating and transforming data for IoT-fueled analysis and optimisation

- Code-free development environment accelerates configuration of rich web-enabled dashboards and applications through a library of widgets

SAN RAMON, Calif. – MARCH 10, 2022 — GE Digital today announced updates to Proficy® Operations Hub, the company’s modern, centralised environment for rapidly building industrial applications for web-based intelligence. Proficy Operations Hub 2022 improves plant operations by enabling the connected worker through access to aggregated, cross-systems information that makes it easier to analyse and act upon independent of location.

Proficy Operations Hub allows both developers and non-developers to quickly assemble displays through a comprehensive library of widgets and arrange them to provide responsive operator and supervisor visualisation. Companies can define data sources for connected devices and create queries to access and transform data into actionable information for operations. Drag-and-drop design allows for simple placement and configuration of visualisation components on the display, then dragging the query or data source onto the component quickly enables the data connections.

Designed as an OT business intelligence (BI) tool for any industrial environment, Proficy Operations Hub is used in diverse industries including water/wastewater treatment, automotive manufacturing, food and beverage processing, power and energy, and consumer goods.

As an example, ENGIE, a global company in low-carbon energy and services, worked with Control & Protection Automation NV (CPA) to leverage Proficy Operations Hub to accelerate time to value. The team developed and delivered an expanded remote and local monitoring and control solution. CPA maximised Proficy Operation Hub’s Rapid Application Development (RAD) capabilities in conjunction with the Proficy software portfolio to create reusable objects and High Performance HMI operator screens, GIS functionality, dashboards, and more.

New features in this latest update include increasing Rapid Application Development using cloud infrastructure with Microsoft® Azure and Amazon® Web Services (AWS), an expanded widget library for data display and analysis, and third-party systems integration enabled by OPC UA. The software also enhances OT BI with new visualisation widgets for supervisory dashboards and a pivot grid for ad hoc multi-dimensional data analysis.

Proficy Operations Hub further enhances a company’s MES, HMI/SCADA, and Historian applications with a data flow editor for creating runtime logic to transform data for visualisation, creating a foundation for IoT-fueled analysis and optimisation. A new multi-timeline widget enhances the display of event-based data such as downtime and machine/equipment utilisation. Improved operator experience for Life Sciences customers is also enabled with a new customisable Proficy® Batch Execution application for operators.

“Access to data across the organization provides faster response and better decision-making with centralised visualisation, digitised processes, and data analysis in context. Ultimately that leads to decreased costs and time to market as well as lower maintenance costs,” said Richard Kenedi, General Manager for GE Digital’s Manufacturing and Digital Plant business. “These outcomes are the result of improved collaboration and continuous improvement programs that are key performance indicators in the industrial environment today.”